When it comes to industrial flooring, the question is never “what’s the strongest floor?” but rather “what’s the right floor for my environment?”

From factories to warehouses, food facilities to workshops, flooring isn’t just about looks — it’s about safety, durability, hygiene, and long-term cost savings. In this post, we’ll compare the most common types of industrial flooring, highlight their strengths and weaknesses, and give you a framework to choose the best solution for your facility.

Content

Why Flooring Matters More Than You Think

Industrial floors are exposed to more abuse in a year than most residential floors see in a lifetime. Forklifts, dropped tools, chemical spills, temperature swings, constant cleaning — the wrong choice can cost you downtime, expensive repairs, and even safety risks.

So, let’s break down the contenders.

Industrial Flooring Options Compared

| Flooring Type | Strengths | Weaknesses | Ideal Use Cases |

|---|---|---|---|

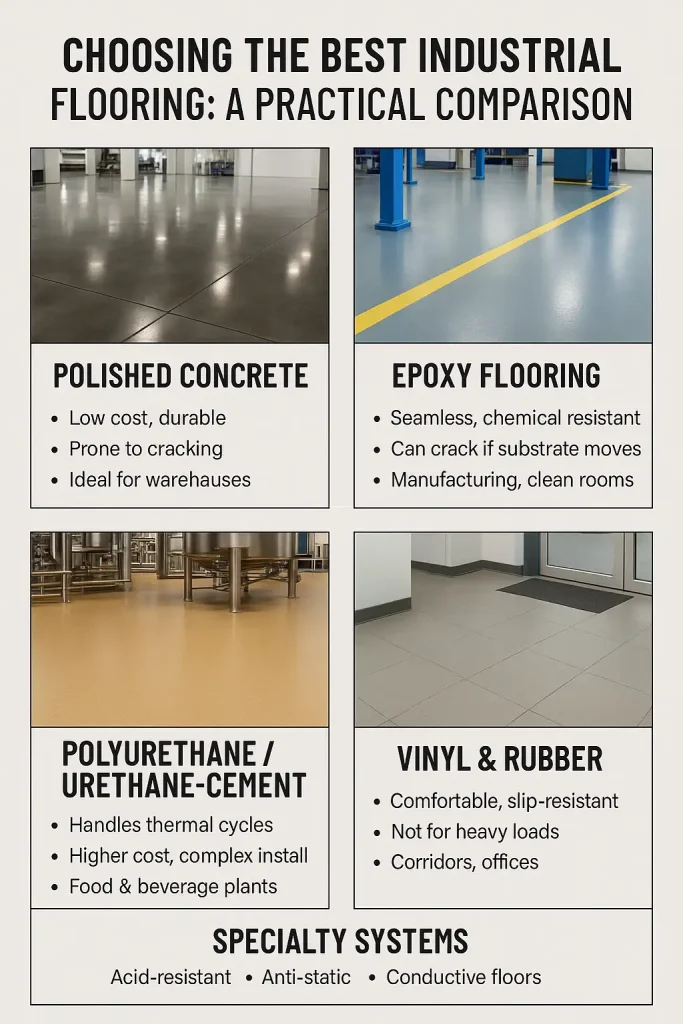

| Polished Concrete | Low cost, durable, reflective surface, long lifespan | Prone to cracking, limited chemical resistance, hard on workers’ feet | Warehouses, storage zones, baseline substrate |

| Epoxy Flooring | Seamless, high hardness, chemical resistant, customizable colors/finishes | Can crack if substrate moves, not UV stable, prep-sensitive | Manufacturing, clean rooms, moderate traffic |

| Polyurethane / Urethane-Cement | Flexible, handles thermal cycles, excellent impact resistance | Higher cost, complex installation | Food & beverage plants, facilities with vibration/heat |

| Polyaspartic / Polyurea | Fast cure, UV stable, durable | Expensive, skilled installation required | Facilities that can’t afford long downtime |

| Vinyl & Rubber | Comfortable, slip-resistant, noise reduction | Not for heavy loads, lower durability | Corridors, offices near industrial areas |

| Specialty Systems (acid-resistant, anti-static, conductive) | Designed for extreme needs, compliance-friendly | High cost, niche installation | Chemical plants, cleanrooms, electronics assembly |

The Decision Framework

Instead of asking “which is the best,” ask:

- What loads will the floor carry? (foot traffic, forklifts, heavy machines)

- What exposures are common? (chemicals, heat, vibration, UV, water)

- How fast do you need installation? (hours vs days of downtime)

- What compliance or safety standards matter? (slip resistance, HACCP, anti-static)

- What’s the total cost of ownership? (not just install cost, but maintenance + repairs)

In many facilities, the answer isn’t one floor but a combination: epoxy in the machine area, polyurethane cement in food processing, vinyl in offices, polished concrete in warehouses.

Final Thoughts

The “best” industrial flooring is the one that matches your operations, environment, and budget. A shiny epoxy might look impressive, but if your facility experiences temperature swings or chemical spills, you’ll need something tougher.

If in doubt, partner with an experienced flooring specialist who can assess your site and recommend a tailored solution. Remember: the cost of choosing wrong isn’t just in materials, but in downtime, safety, and long-term repairs.

For more detail visit now: egcore-co.com

Christine Kelley is a dedicated home blogger who has been blogging for over six years. She covers everything home related. Christine also loves writing posts about her travels to Europe with her husband and two children.