Most DIY enthusiasts like to use epoxy resin for their project because of the ability to adapt well of the material. Like WD-40, it was first made for aerospace technology but because of the low price, it began to be sold to the public and can be obtained by anyone. You can also find epoxy resin at any retail store with various brands and price.

For those who never seen epoxy resin before, it comes with two parts, the epoxy and the hardener. Both are usually sold together. It is separated for a long time keeping and to customize the mixture according to the user’s need.

I will try to avoid using scientific terms here because most people don’t care about it and they only interested in what the epoxy can do.

Combining both liquids makes a workable fluid which is usually clear in color that can be mold to any shape and sizes. The solidification can be determined by the user according to their specification, weather, temperature and the place of the working environment. The hardened resin is non-sticky, clear, and can be sanded for perfect finishing.

Epoxy resin properties consist of the ability to adapt, very hard physical quality, and very strong bonding ability. Epoxy resins can be mixed with other additive substance or another hardener.

Common use of epoxy are to stick glass windows and wall, to build custom car body kit (used with carbon fibers), bonding broken structures and many more. While the color of epoxy is clear, you can add color by mixing it with another hardener. You can make pastes, mold structures and even make jewelry.

If mixed accurately, epoxy is one of the best adhesive available. Besides mixed accurately, the condition of the applied surface must be clean. You can bond almost anything with epoxies such as wood, metal, glass, fibers and plastic.

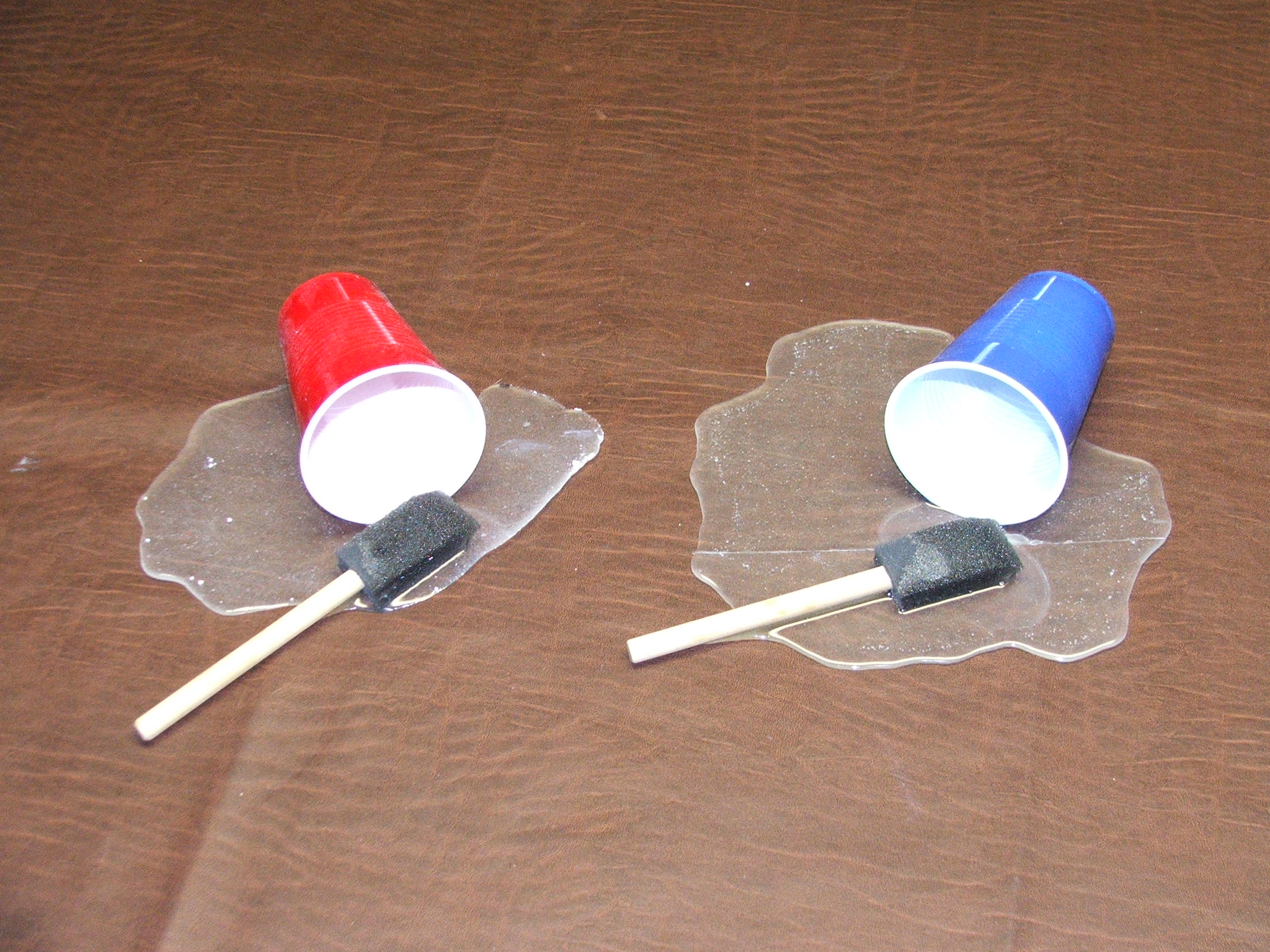

Before applying to the medium, you must test it first in a small scale. This is the vital part and even a professional will do a test before utilizing epoxy. Make an experiment and wait for it to solidify, while observing the accessible working time. At that point, where conceivable, test a little specimen with the repair materials to check for wanted results. This will reduce errors when applying it on the project and to have an excellent finish.

The conclusion of the use of epoxy resin:

- As a glue for metals, glass, plastic, wood, clay, and so forth.

- Creating a physical object that can be redesign like a solid iceberg

- As a working medium that can be formed into complex shapes to completed measurements

- As a mold substrate and structure for forming different materials

Always remember that this wonderful tool contains high chemical mixture which can be hazardous to our health. Every user is advised to use proper protection and the appropriate safety procedures during handling epoxy. There could be an existence of any harmful chemicals mixed together.

The best thing to do is to read the instructions that come with the product. Any information from the manufacturer is very important for the user.

I’m Carrie Phillips. I love to share my tips and tricks for home improvement, as well as provide ideas for how you can transform your space with DIY projects.